This post about a ceiling makeover is sponsored by The Home Depot. It’s quite possible that your home has some secret treasures just waiting to be uncovered. Whether it’s removing a ceiling to expose the wood beams, reconfiguring your bathroom layout or installing additional lighting it’s all within your reach.

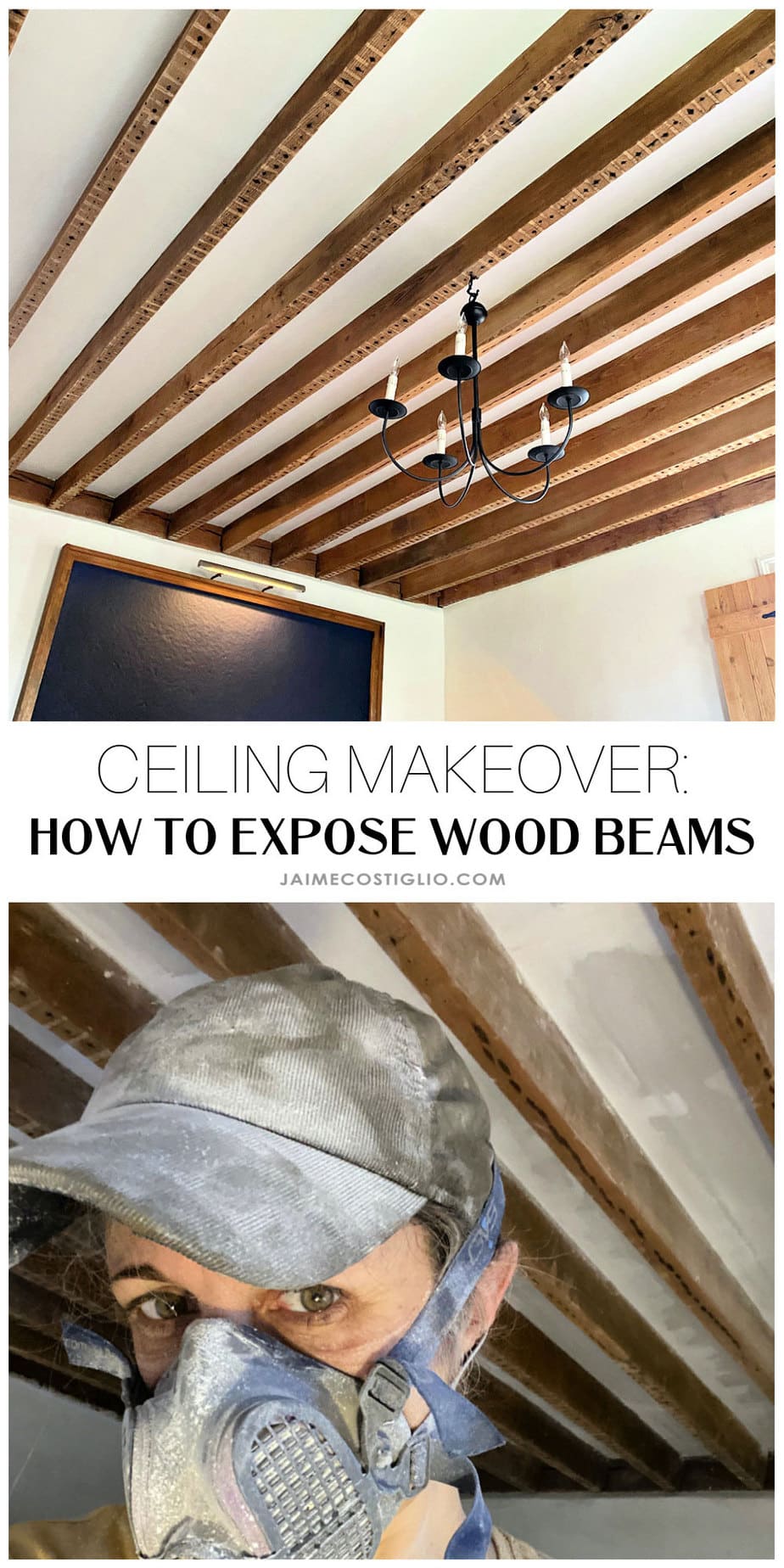

A DIY tutorial to makeover your ceiling and expose wood beams. Step by step instructions to remove the ceiling and expose wood beams.

Meet my newly exposed wood beams! They’ve been hiding for years under a thick layer of plaster and lath and are now ready for their debut.

Doers Get Things Done

I’m a doer. I take great pride in doing all the home improvements and this ceiling makeover may just be my best project yet. But I could not have done it without the help of The Home Depot Delivery Pros and their delivery option for online orders. Did you know they have over one million items you can have delivered to your doorstep for free?!

Let’s back up for one minute and start at the beginning.

Ceiling Before:

This room is what’s known as the keeping room in a traditional primitive saltbox farmhouse. Sort of the early version of a family room before cushy sofas and TVs were invented.

And now that very same room has beautiful, exposed wood beams! With a bit of DIY muscle power and the awesome delivery service from The Home Depot I was able to complete this ceiling makeover.

Step one for this project was to order all the necessary supplies. When you are tackling a large project that involves big, heavy supplies I highly recommend delivery.

Home Depot Delivery Pros:

- order everything you need online and save a trip to the store

- flexible delivery options

- free delivery on over a million items

- expanded return window on unopened items

Taking on a project like this can seem daunting but it’s definitely possible. I’m just a mom getting things done with the help of this delivery solution from The Home Depot.

How-To

If you’re not sure where to start I highly recommend browsing the How-To videos and tutorials on at homedepot.com. They have thousands of how-to videos for projects and repairs you need to make at home.

For this ceiling makeover project I have some prior experience to fall back on. Many years ago I removed the ceiling in our dining room and more recently the ceiling in the master bedroom. So, I can confidently proceed with this third ceiling project. And I’m happy to share the tutorial details down below if you’re wanting to expose the wood beams in your home.

Ceiling Makeover: Where to Begin

- determine all necessary supplies (see my supply list below) and place an online order for delivery

- prepare the space

- take it one step at a time – it will feel overwhelming so small steps will help overcome this feeling

- mentally prepare yourself it will take longer than you think

- plaster is extremely dusty and dust travels – dust mitigation is your number one concern when preparing

Then when it’s all over you can marvel at the warm, inviting space you have now created!

Exposed Wood Beams

This view above is peeking into our master bedroom where I exposed the beams a few years ago.

And you may discover some amazing details along the way like these roman numerals that were chiseled into the horizontal beam. Classic post and beam construction means the joist slots were labeled with roman numerals for the corresponding joist.

Let’s get to the nitty gritty!

Supplies:

- ram board

- ram board tape

- pry bar

- hammer

- multi-tool with flush cut blade

- 3/8″ sheetrock

- utility knife

- sawhorses

- 2×2 furring strips

- 2 1/2″ spax screws

- impact driver

- measuring tape

- 1 1/4″ drywall screws

- joint compound

- drywall joint tape

- joint compound knife

- drywall hand sander

- sanding blocks

- primer

- white ceiling paint

- shortcut 2″ angled brush

- 6″ foam roller

My delivery from The Home Depot arrived complete with plastic covering to protect the lumber and sheetrock from moisture.

Step 1: Remove all furniture from the space and lay down ram board. When you knock the plaster from the ceiling it slams to the floor (sometimes in big sections) so you’ll want to protect the floor and keep dust under control. Be sure to go up the wall with the ram board and use ram board tape on the seams.

- cover outlets with painters tape

- close HVAC vents and seal with a piece of ram board and tape

- cover and seal all doorways with heavy plastic and painters tape, I recommend 2 layers

- wrap any stationary items with plastic (like the interior shutters)

- open all windows

- prepare to collect and remove plaster and lath as required (check construction disposal rules in your town)

- spray bottle with water (helps to keep dust settled)

- apply carpet plastic to wood floors above to keep dust from traveling between the cracks

Plaster Removal

Step 2: Using a flush cut blade on a multi-tool cut through the seam where the wall meets the ceiling. Work in sections, you don’t want to cut all four sides of the room at once. Making this cut will release the plaster from the wall. Then begin by hammering upwards on the plaster to loosen it from the lath.

In a typical plaster and lath ceiling the plaster is smooshed onto wood lath and the wood lath is nailed on the joists. You need to loosen the plaster from the lath and then remove the lath.

Step 3: In my experience it’s much easier to hammer the ‘keys’ of the plaster from above – inside the cavity between the joists. This allows the plaster to fall. Then you can pry the lath from the joists.

You’ll want to suit up entirely for this process. Then once the seam at the wall is cut the only tools you need are a hammer and pry bar.

The majority of plaster in our home is horsehair plaster. You may find big chunks of horsehair mixed in with the plaster.

You can clearly see the post and beam construction here at the corner along with the wood pegs. I absolutely marvel at primitive construction. The carpenters of colonial days are my heros!

Step 4: Now that all the lath is gone you are left with a bazillion nails. Remove all the nails with a pry bar.

Step 5: In order to install sheetrock up in the cavities we need to first attach furring strips so we have something to attach the sheetrock to. This also creates a 1 ½” gap between the floor boards and sheetrock should you wish to run electrical.

Screw the cleats to the joists using 2 ½” spax wood screws. Be sure to leave a ¼” gap where the cleat meets the floorboard. This allows for any wood movement in the floors above (seasonal changes, people walking, weight of furniture, etc).

Step 6: Now is the best time to sand the joists. Sanding removes years of dirt and dust and smooths any rough areas.

Step 7: Measure each cavity and cut the sheetrock to fit. This will be tedious and hard because each cavity is a slightly different size, sheetrock is heavy and you’re working overhead. Score and snap the sheetrock then install using 1 ¼” drywall screws.

Step 8: Use joint compound to fill any gaps and tape seams where sheetrock pieces meet. Don’t worry if you get compound on the wood, it will wash off later.

You can see the seams above in the exterior wall above the windows where I had to install small pieces of sheetrock between each joist.

Step 9: Once the joint compound is dry then sand the drywall. Again a very messy and dusty process.

Now that the drywall is all sanded we will clean the exposed wood beams.

Step 10: Wash the wood beams to remove any excess joint compound and dust. Use your joint compound knife to protect the sheetrock as you scrub the wood. You don’t want to saturate the drywall so the knife protects it while you clean the wood.

Step 11: Prime the drywall. Cut in on both sides using a 2” angled shortcut brush and then roll the remaining area with a foam roller. I recommend two coats of primer and then two coats of flat white ceiling paint.

Now clean up all the dust and move the furniture into the space. Amazing what we can accomplish with determination and a delivery of supplies!

Thanks for joining me for this ceiling makeover project. Please leave any questions in the comments below and be sure to follow me on social media for sneak peeks, tools and project inspiration:

SHOP THIS PROJECT:

Très bon travail merci

Thank you Dominique, it was so worth it!

This is my first comment (that I can remember!) but I am so impressed with all the hard work and the beauty of your finished product that I have to say this is amazing! You’ve done a wonderful job Ma’am!

Thanks for sharing!

Did you ever put insulation between the sheet rock and the beams?

Hi Lori, I never put insulation in-between the sheetrock and floor boards. Yes you can hear someone walking around above as the floorboards naturally move and squeak. I haven’t done any research about insulating so I’m not sure if it’s a good idea or not.

Hard work makes dreams come true! Beautiful job.

Thanks Janina, so much work but I’m so happy to be on the other side of this project. And I think those wood beams like showing off!

Beautiful job Jaime! Incredible that you did it all yourself – but I am not at all surprised.

Thanks Lisa, you know me too well ;). We LOVE this room and spend all our time in here now especially those working / schooling from home.

Such an amazing end result but so much hard work involved! I admire your determination and skills to see this through! Keep it up!

Thanks Bryant, makes it all worth it!

This is utterly fantastic

Great vision for what you wanted, and very solid methodology in achieving it.

Not to mention the crazy hard work.

Something to really be proud of.

Thank you Sean, it was a ton of work but so worth it. I’m so darn happy I finally tackled this one – now all the downstairs rooms in the original part of out home have ‘matching’ ceilings.

I’m curious if you used anything special to clean the beams? What solution did you use?

Hi Dianne, nothing special. I sanded them first then washed with sponge and water. That’s it. I do vacuum them from time to time for dust bunnies.

Hi! I love this room. I was wondering what paint color the green is. thanks!

Thanks Kristin, we love it too! Honestly we spend so much time in here now that it’s all nice, welcoming and cozy. The green beadboard wall is painted Benjamin Moore Old Salem Gray.

Beautiful job! How long did you approximately take? I’m so tempted…inspired, to do the same to our family room

Nice. Exactly what I am think about for our 1937 home in SoCal

Good to see that the exposed beams will look quite rough due to the lath and plaster ceiling being nailed into it for a long time. I probably would now consider painting the beams after seeing it. But that is not a knock on leaving them raw which has it’s own esthetic.

How long did it end up taking you? Looks great!! Thank you for the inspiration.

I did something similar but chose to insulate (mineral wool) between the joists before putting sheetrock in. If you bring your mud out more and use less of it you don’t have to sand that much (if at all).

I painted my sheetrock flat black to show off the joists and not the ceiling. I caulked in between the rafters and sheetrock with black latex calk, which is pretty much invisible.

Great job.

Mostrarnos con fotos

This is so helpful, thanks so much for the detailed instructions! Tackling the same project on our 1840’s home… your site is really inspiring! Not sure if you’re monitoring this post anymore but I’d love to know what color green you used on your fireplace.

Oh actually, I just saw another commenter asked the same thing, Benjamin Moore Old Salem Gray… gorgeous!

Hi Kristin, Great to hear from other old home owner folks 🙂 Yes Old Salem Gray is the paint on the fireplace and wall. More details on that wall here: https://jaimecostiglio.com/make-your-own-beadboard-paneling/

Good luck with your project!

Good work Jamie, your finished rooms look wonderful. My plaster panels are in place and painted, yet half of the 1865 farm house beams have lathing plaster scars. NOW Here’s The Question. What’s the best way to remove the plaster scars from the bottom of the beams? The Brazillion nails have already been been removed.

Thanks Paul, I still have plaster scars on most of my beams. I did give them a good sanding with 150 grit to smooth everything down but the white scars are visible for certain. Sorry I don’t have a good answer 🙂

Doing similar project in my victorian house cellar. Joists very irregular so hard to get plasterboard to a consistent proximity to joist edges as variable distances and angulation of joists. Mounting on metal angle as I was advised by a friend that less likely to cause cracks in plasterboard than when mounted on wood but I don’t know if that is true. Tips on how to avoid future cracking of the jointing compound in the small gaps at edges gratefully received. Some form of plastic edge bead could help but unsure how it would work in this situation esp as metal angle is thin width(25mm) so unable to leave a planned gap on side of plasterboard and hoping not to need to skim it fully.

I removed the lathe/plaster white strips by electric planing the joist bottoms before sanding which was very effective.

Hi Mike, great to hear from others in the same boat. I have done the 3 main rooms with the same process – wood furring 2×2 attached to joists, sheetrock cut to fit between joists then attached to furring, joint compound to finish. The oldest room was done 7 years ago and I have had zero cracking of the compound.